Question:

During extraction of aluminium from bauxite,

During extraction of aluminium from bauxite,

Updated On: Jun 7, 2022

- the concentration of ore is done by gravity separation method

- molten mixture of aluminium oxide, cryolite and fluorspar is electrolysed

- impure aluminium is refined by liquation

- molten aluminium is obtained at cathode while fluorine is liberated at anode.

Hide Solution

Verified By Collegedunia

The Correct Option is B

Solution and Explanation

Purified ${Al_2O_3}$ is mixed with ${Na_3AlF_6}$ and ${CaF_2}$ to improve conductivity of ${Al_2O_3}$ and to lower the melting point of the mixture.

${Al_2O_3 ->[Electrolysis] 2Al^{3+} + 3O^{2-}} $

At cathode : ${Al^{3+} + 3e^- ? Al}$

At anode : ${C + O^{2-} ? CO + 2e^-}$

${ C + 2O^{2-} \rightarrow CO_2 + 4e^-}$

${Al_2O_3 ->[Electrolysis] 2Al^{3+} + 3O^{2-}} $

At cathode : ${Al^{3+} + 3e^- ? Al}$

At anode : ${C + O^{2-} ? CO + 2e^-}$

${ C + 2O^{2-} \rightarrow CO_2 + 4e^-}$

Was this answer helpful?

0

0

Top Questions on General Principles and Processes of Isolation of Elements

- What is used for the Thermite Reaction?

- BCECE - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- In the extraction of iron using blast furnace to remove the impurity (X), chemical (Y) is added to the ore. X and Y are respectively

- TS EAMCET - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- Which of the following compounds is used to cover the surface of a metallic object to prevent corrosion?

- KEAM - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- The incorrect statement about the Hall-Heroult process is:

- KCET - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

- Select the correct statement:

- KCET - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

View More Questions

Questions Asked in JIPMER exam

- Binomial nomenclature was first introduced by

- JIPMER - 2015

- KCET - 2022

- Diversity In The Living World

- $2,4-DNP $ test can be used to identify :

- JIPMER - 2021

- Chemical Reactions

- A convex lens $'A'$ of focal length $20\, cm$ and a concave lens $'B'$ of focal length $5\, cm$ are kept along the same axis with a distance $'d'$ between them. If a parallel beam of light falling on $'A'$ leaves $'B'$ as a parallel beam, then the distance $'d'$ in cm will be :

- JIPMER - 2021

- Spherical Mirrors

- A bacterial flagellum is composed of

- JIPMER - 2021

- Prokaryotic Cells

- How many moles of acidified $K_2Cr_2O_7$ is required to liberate $6$ moles of $I_2$ from an aqueous solution of $I^-$ ?

- JIPMER - 2020

- Mole concept and Molar Masses

View More Questions

Concepts Used:

General Principles and Processes of Isolation of Elements

What are Ores and Minerals?

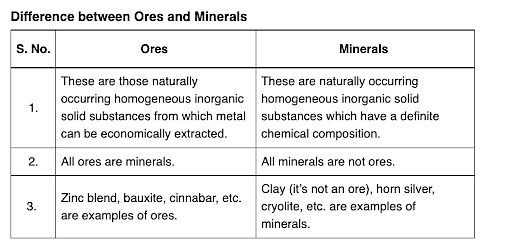

Minerals are the naturally occurring, homogeneous inorganic solid substances. They are having a definite chemical composition and crystalline structure, hardness and color. For example, copper pyrite, calamine, etc.

Impurities in an ore are called gauge. The removal of a gauge from the ore is called concentration ore.

Several steps are involved in the extraction of pure metal from ores. Major steps are as follows –

- Concentration of the ore

- Isolation of the metal from its concentrated ore

- Purification of the metal