The metal refined by Van Arkel method is

The metal refined by Van Arkel method is

Ni

Zr

Cu

Sn

The Correct Option is B

Solution and Explanation

The metal refined by the Van Arkel method is Zr (Zirconium).

The Van Arkel method, also known as the iodide process, is a technique used for the purification of certain metals, including zirconium. In this method, the metal is converted into a volatile metal iodide, which is then decomposed to obtain pure metal. The Van Arkel method is commonly used for the purification and production of high-purity zirconium metal.

Top Questions on General Principles and Processes of Isolation of Elements

- What is used for the Thermite Reaction?

- BCECE - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- In the extraction of iron using blast furnace to remove the impurity (X), chemical (Y) is added to the ore. X and Y are respectively

- TS EAMCET - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- Which of the following compounds is used to cover the surface of a metallic object to prevent corrosion?

- KEAM - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- The incorrect statement about the Hall-Heroult process is:

- KCET - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

- Select the correct statement:

- KCET - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

Questions Asked in CUET exam

- Find the ratio of de-Broglie wavelengths of deuteron having energy E and \(\alpha\)-particle having energy 2E :

- CUET (UG) - 2026

- Dual nature of radiation and matter

- If 36: 84 :: 42: X, then the value of X, is:

- CUET (UG) - 2025

- Ratio and Proportion

- The angles of elevation of the top of a tower from two points at a distance of 5 meters and 20 meters along the same straight line from the base of the tower, are complementary. Find the height of the tower.

- CUET (UG) - 2025

- Trigonometry

- Had he ________ the importance of the meeting, he would have made sure to attend.

Rearrange the following parts to form a meaningful and grammatically correct sentence:

P. a healthy diet and regular exercise

Q. are important habits

R. that help maintain good physical and mental health

S. especially in today's busy world- CUET (UG) - 2025

- Sentence Arrangement

Concepts Used:

General Principles and Processes of Isolation of Elements

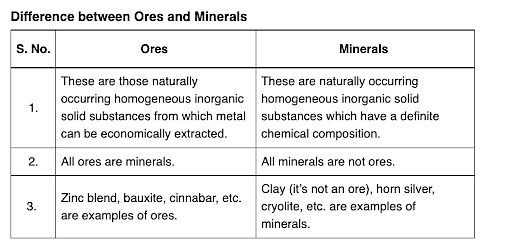

What are Ores and Minerals?

Minerals are the naturally occurring, homogeneous inorganic solid substances. They are having a definite chemical composition and crystalline structure, hardness and color. For example, copper pyrite, calamine, etc.

Impurities in an ore are called gauge. The removal of a gauge from the ore is called concentration ore.

Several steps are involved in the extraction of pure metal from ores. Major steps are as follows –

- Concentration of the ore

- Isolation of the metal from its concentrated ore

- Purification of the metal