Question:

Aluminium is obtained by

Aluminium is obtained by

Updated On: Jun 3, 2023

- reducing $Al_2O_3$ with coke

- electrolysing $Al_2O_3$ dissolved in $Na_3AlF_6$

- reducing $Al_2O_3$ with chromium

- heating alumina with cryolite

Hide Solution

Verified By Collegedunia

The Correct Option is B

Approach Solution - 1

Electrolytic reduction

Was this answer helpful?

0

0

Hide Solution

Verified By Collegedunia

Approach Solution -2

Aluminum can't be made by reducing its ore, alumina, with coke. This is due to the fact that alumina is a highly stable oxide and that aluminum has a strong affinity for oxygen. As a result, coke cannot turn alumina to aluminum metal, which is then transformed to carbon dioxide.

The electrolysis of Al2O3 dissolved in Na3AlF6 yields aluminum. Because pure aluminum oxide has a high melting point, it is combined with cryolite to reduce the melting temperature from 200\(^{\circ}\)C to 600\(^{\circ}\)C.

The following equations depict the electrolysis of molten bauxite in the presence of cryolite:

Al+3+3e-→Al (At the cathode)

C +2O2-→CO2 + 4e- (At the anode)

During the electrolysis process, positively charged aluminum ions move towards the cathode, while negatively charged oxygen and fluoride ions move towards the positively charged anode, Because oxygen is less electronegative, it is discharged over fluoride as carbon dioxide gas in reaction with the carbon anode.

The electrolysis of Al2O3 dissolved in Na3AlF6 yields aluminum. Because pure aluminum oxide has a high melting point, it is combined with cryolite to reduce the melting temperature from 200\(^{\circ}\)C to 600\(^{\circ}\)C.

The following equations depict the electrolysis of molten bauxite in the presence of cryolite:

Al+3+3e-→Al (At the cathode)

C +2O2-→CO2 + 4e- (At the anode)

During the electrolysis process, positively charged aluminum ions move towards the cathode, while negatively charged oxygen and fluoride ions move towards the positively charged anode, Because oxygen is less electronegative, it is discharged over fluoride as carbon dioxide gas in reaction with the carbon anode.

Was this answer helpful?

0

0

Top Questions on General Principles and Processes of Isolation of Elements

- What is used for the Thermite Reaction?

- BCECE - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- In the extraction of iron using blast furnace to remove the impurity (X), chemical (Y) is added to the ore. X and Y are respectively

- TS EAMCET - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- Which of the following compounds is used to cover the surface of a metallic object to prevent corrosion?

- KEAM - 2025

- Chemistry

- General Principles and Processes of Isolation of Elements

- The incorrect statement about the Hall-Heroult process is:

- KCET - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

- Select the correct statement:

- KCET - 2024

- Chemistry

- General Principles and Processes of Isolation of Elements

View More Questions

Concepts Used:

General Principles and Processes of Isolation of Elements

What are Ores and Minerals?

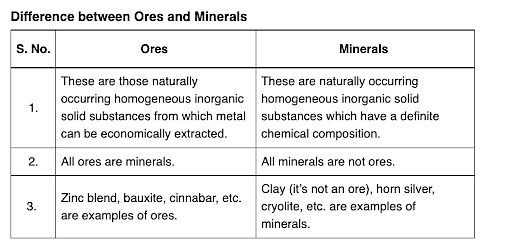

Minerals are the naturally occurring, homogeneous inorganic solid substances. They are having a definite chemical composition and crystalline structure, hardness and color. For example, copper pyrite, calamine, etc.

Impurities in an ore are called gauge. The removal of a gauge from the ore is called concentration ore.

Several steps are involved in the extraction of pure metal from ores. Major steps are as follows –

- Concentration of the ore

- Isolation of the metal from its concentrated ore

- Purification of the metal